UT Dallas leads $30M Battery Technology Initiative

The University of Texas at Dallas is leading a $30 million initiative to boost domestic production of batteries, develop next-generation battery technologies and train workers for jobs in the growing industry.

The Department of Defense-funded project aims to strengthen the U.S. supply chain of batteries, most of which are manufactured in China. The initiative creates a prototype Energy Storage Systems Campus expected to leverage and stimulate over $200 million in private capital. The agreement to establish the Batteries and Energy to Advance Commercialization and National Security (BEACONS) center provides funding from the DOD’s Manufacturing Capability Expansion and Investment Prioritization Directorate.

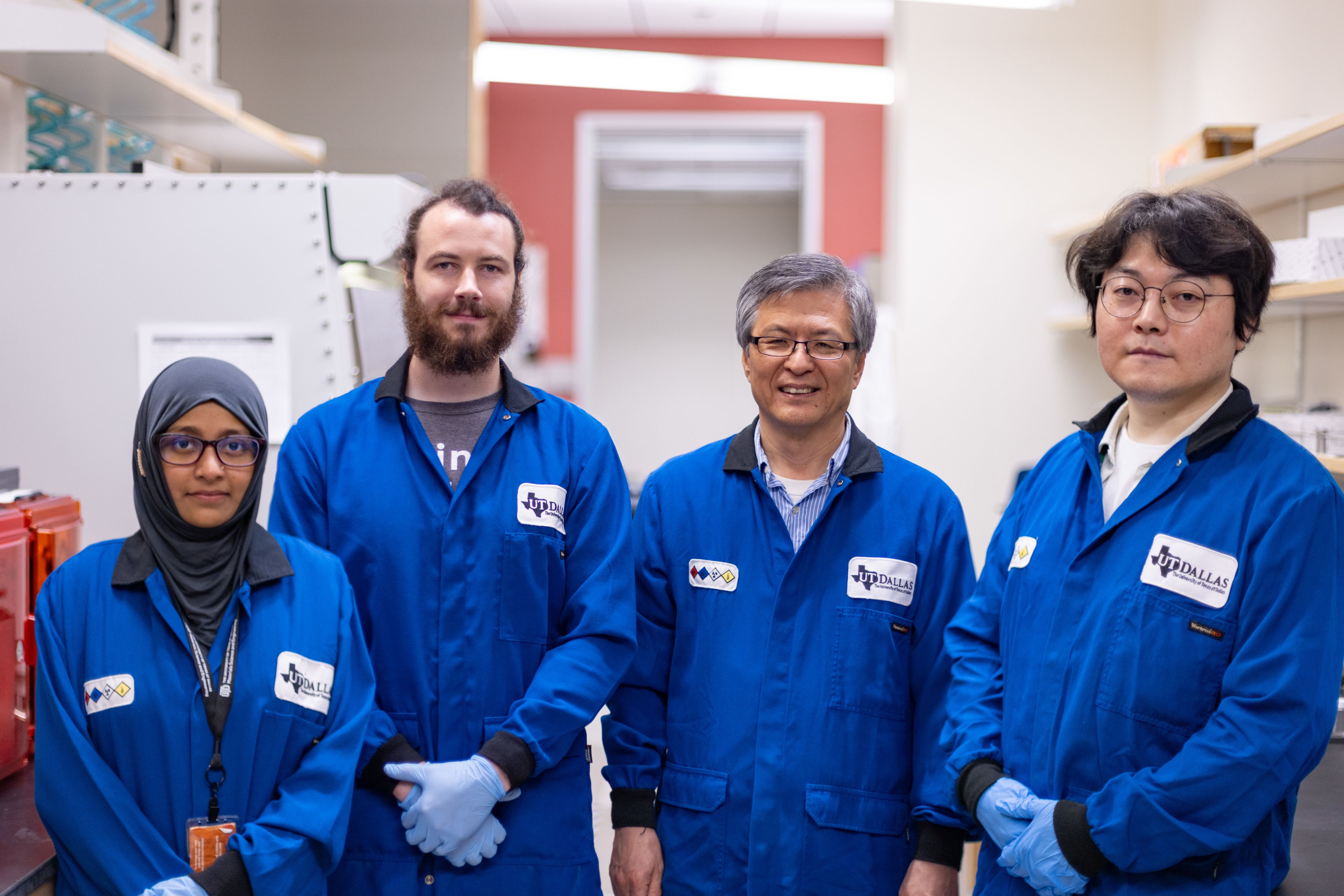

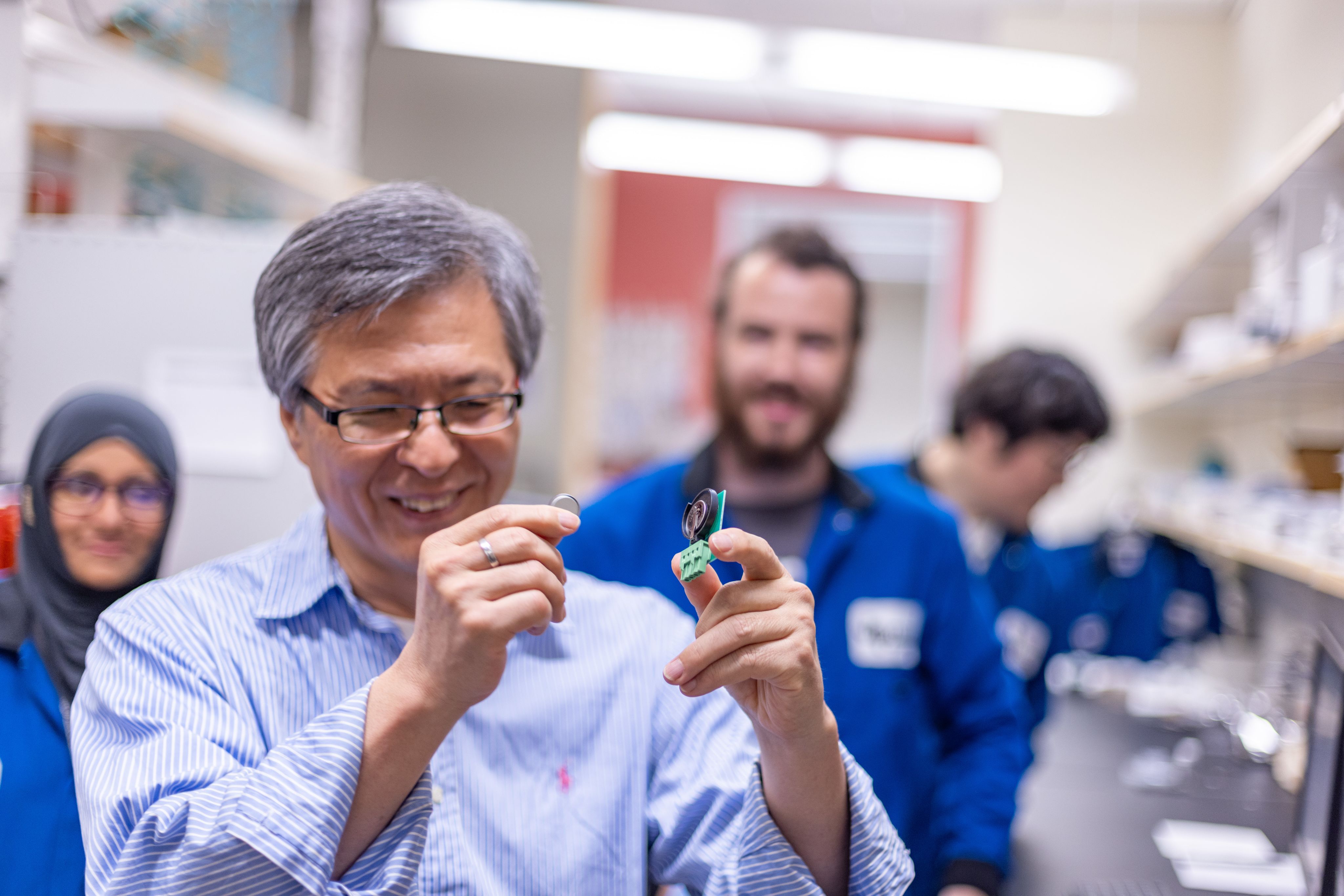

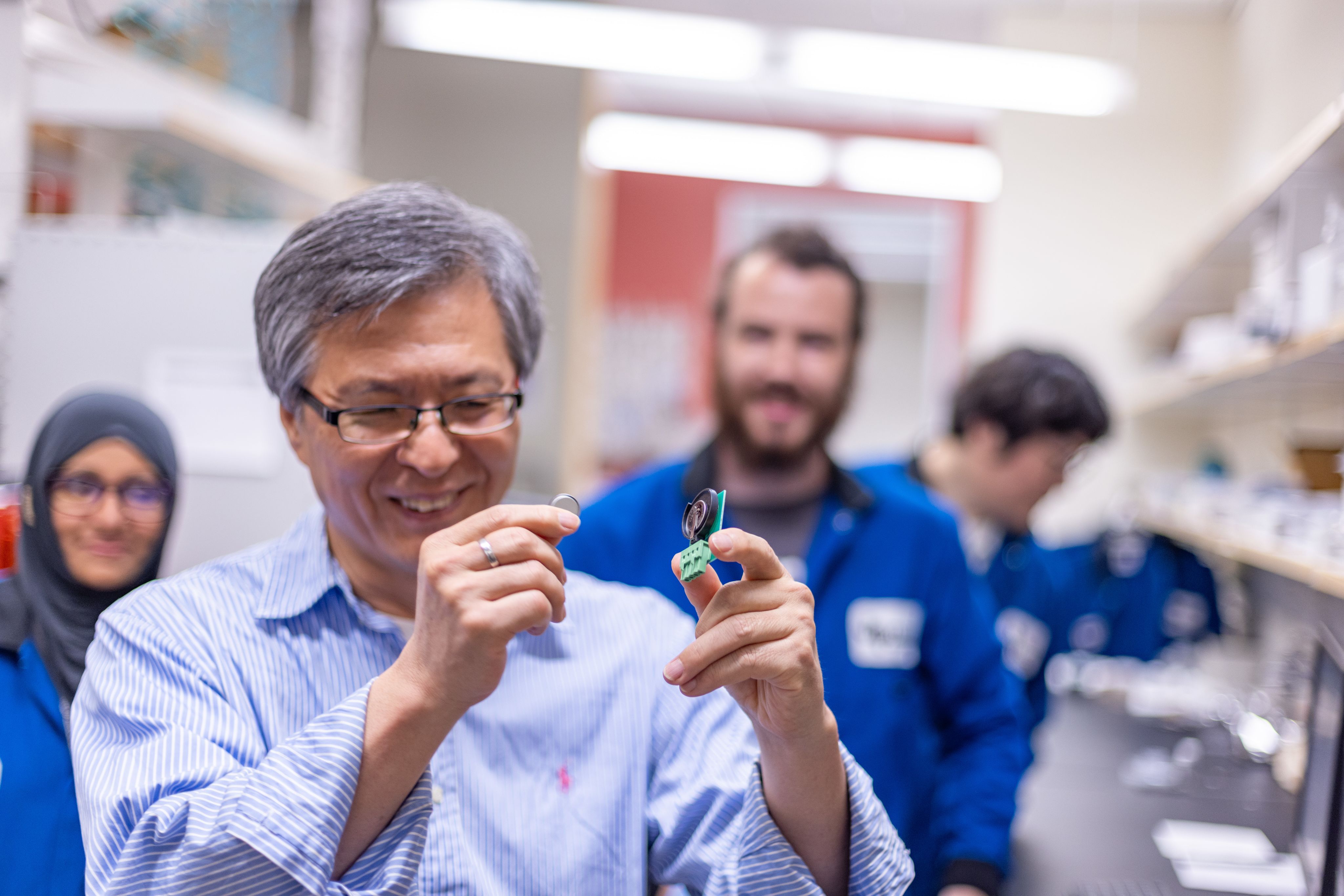

Dr. Kyeongjae Cho, professor of materials science and engineering in the Erik Jonsson School of Engineering and Computer Science at UTD and co-principal investigator, explains the project and its impact.

Q: What is the purpose of the BEACONS center?

A: The center focuses on four main goals:

- Optimizing existing battery systems, including integrating robotics and automation into manufacturing.

- Fostering the development of new battery chemistries that reduce the use of scarce raw materials.

- Identifying and tracking supply chain challenges for critical minerals, such as lithium, needed in energy storage systems.

- Developing the workforce needed for energy storage system development and manufacturing.

In addition, the initiative will provide access to facilities to help entrepreneurs design, develop and demonstrate novel energy storage systems.

Q: Why is this important?

A: Batteries power phones, computers, electric cars and many other technologies in addition to defense applications. However, few batteries are manufactured in the U.S. While the U.S. has been a leader in battery research and technology development, battery manufacturing and supplies of critical raw materials have traditionally been located outside of the country. The DOD initiative reflects efforts to bring advanced manufacturing and supply chains to the U.S., which is critical to help the nation avoid supply chain disruptions like ones that led to semiconductor shortages during the pandemic. This investment by the DOD will facilitate collaboration with our industry partners to help ensure reliable, domestic manufacture of lithium-ion cells, as well as the battery packs that support defense systems and advanced commercial systems.

Q: How will UT Dallas researchers be involved?

A: BEACONS will include multiple UTD researchers in the Jonsson School and the School of Natural Sciences and Mathematics who work on energy storage technology, including experts in computer modeling, artificial intelligence, chemistry, prototyping and commercialization. Their work will center on developing safer, longer-lasting and more efficient next-generation battery technology, including alternatives to traditional lithium-ion cells. Lithium-ion batteries, which power everything from consumer electronics to electric vehicles, have disadvantages: They are sensitive to high temperatures and thermal runaway reactions, which can cause fires; they are difficult to recycle; and they require the expensive mining and processing of rare raw materials, such as lithium, nickel and cobalt.

UTD researchers are investigating current battery system optimization as well as next-generation batteries with alternative materials and designs, such as solid-state batteries, which use solid electrolytes instead of organic liquids or polymers, and aqueous zinc-ion batteries, which are made from raw materials that are more abundant.

Q: Where will the BEACONS center be located?

A: The UTD-led initiative will include construction of a battery research facility located on the the UT Dallas campus. The facility will include space for developing and manufacturing next-generation batteries, as well as energy storage solutions specifically tailored to defense applications. For example, defense systems operate at extremely cold or hot temperatures, encounter high shock and vibration, and may be stored for long periods then needed quickly for immediate use. Defense battery systems also are sometimes operated in environments where safety demands exceed current commercial requirements.

Q: How will the initiative provide workforce development?

A: UTD will partner with community colleges in North Texas to train future employees with a range of expertise, including battery materials and electrochemistry.

A 2020 report from the U.S. Department of Energy’s National Renewable Energy Laboratory projects that the battery energy storage industry will need a minimum of 130,000 additional workers in the U.S. by 2030; at least 12,000 of those workers will be needed in Texas. Earlier this year, Tesla broke ground on a Texas lithium refinery to produce battery metal for electric vehicles.

Renewable energy is a rapidly expanding area, and Texas is leading the country in the expansion of energy storage capacity. We need not only PhD-level experts, but also practical technical experts who know how to safely handle batteries.

This content was paid for and created by The University of Texas at Dallas. The editorial staff of The Chronicle had no role in its preparation. Find out more about paid content.