The Research Powering Economic and Social Progress

How do you take world-leading research out of the ivory tower and achieve tangible impact? At Sheffield, we’ve moved beyond blue-sky thinking. Our translational model, pioneered by the University’s Advanced Manufacturing Research Centre (AMRC) for more than two decades, provides a route for academics to work side-by-side with industry partners to deliver research with purpose.

The University of Sheffield is ranked among the world’s top 100 universities and is a member of the Russell Group - an association of 24 leading, research-intensive universities in the UK that is comparable to the Ivy League in the US. We apply our research globally, forming collaborations with major multinational businesses, international organizations, and governments to address the world’s most urgent challenges.

Based in a city shaped by its industrial heritage, Sheffield has evolved from the heart of Britain’s coal and steel industry into a global hub for advanced manufacturing. Once known for producing the finest cutlery and steel in the world, today we lead the way in high-value manufacturing, partnering with international giants like Boeing and Rolls-Royce.

Our world-class researchers work closely with industry partners who come to the city to collaborate with our AMRC and access its leading facilities. Their joint focus is on solving industrial challenges, from reducing product weight and improving efficiency, to supporting global sustainability goals. This in turn helps to boost businesses productivity and sharpen their competitive edge, while saving time, money and energy.

The AMRC exemplifies Sheffield’s reinvention: a model of how academic insight, when paired with industrial drive, can produce innovation with real impact.

A Pioneering Model for Innovation and Industry Collaboration

The AMRC is a world-leading research and innovation network focused on advanced manufacturing, machining and materials. It originated from an idea to create a centre that bridges the gap between the cutting edge research happening in university labs and the day-to-day needs of the production line. Today, it has grown into a network of 70 universities and more than 1,000 companies of all sizes, from fledgling start-ups and SMEs to the biggest names in manufacturing.

The centre operates on a partnership model, where global manufacturing giants like Boeing, Rolls-Royce, BAE Systems, and Airbus, alongside smaller, critical supply chain companies, directly invest in and guide the research.

Its 576 highly-qualified researchers work with partners to help them improve their productivity and save time, money and energy - a process that ensures the research focuses on real-world operational challenges. They turn the latest world-leading innovations into huge practical improvements for industry - from reducing the time taken to make a component from 40 hours to just three and cutting an assembly process from 60 minutes to 60 seconds, to taking 10 years of production down to 10 weeks.

Our researchers, engineers, and apprentices work together within shared, industrial-scale facilities to solve challenges that could transform entire sectors. This physical co-location is not incidental - it is designed to encourage collaboration and allow our academic community to understand the realities of a day-to-day production line. By pioneering this approach, Sheffield has established its position as a leading location for industrial innovation, creating a blueprint for advanced research and industry collaboration.

A Pioneering Model for Innovation and Industry Collaboration

The AMRC is a world-leading research and innovation network focused on advanced manufacturing, machining and materials. It originated from an idea to create a centre that bridges the gap between the cutting edge research happening in university labs and the day-to-day needs of the production line. Today, it has grown into a network of 70 universities and more than 1,000 companies of all sizes, from fledgling start-ups and SMEs to the biggest names in manufacturing.

The centre operates on a partnership model, where global manufacturing giants like Boeing, Rolls-Royce, BAE Systems, and Airbus, alongside smaller, critical supply chain companies, directly invest in and guide the research.

Its 576 highly-qualified researchers work with partners to help them improve their productivity and save time, money and energy - a process that ensures the research focuses on real-world operational challenges. They turn the latest world-leading innovations into huge practical improvements for industry - from reducing the time taken to make a component from 40 hours to just three and cutting an assembly process from 60 minutes to 60 seconds, to taking 10 years of production down to 10 weeks.

Our researchers, engineers, and apprentices work together within shared, industrial-scale facilities to solve challenges that could transform entire sectors. This physical co-location is not incidental - it is designed to encourage collaboration and allow our academic community to understand the realities of a day-to-day production line. By pioneering this approach, Sheffield has established its position as a leading location for industrial innovation, creating a blueprint for advanced research and industry collaboration.

Extending the Translational Research Model to New Sectors

The High Value Manufacturing (HVM) Catapult is a national network that works with business, research and government to transform UK manufacturing. The University of Sheffield, through its AMRC, is a key member of this network and has helped to transform South Yorkshire into a global exemplar of manufacturing innovation over the last two decades. This translational research model is now being scaled and applied to other sectors such as sustainable energy and neuroscience.

Today, the University of Sheffield has over £350 million worth of translational innovation facilities and assets - including the Energy Innovation Centre (EIC) and the Gene Therapy Innovation and Manufacturing Centre (GTIMC).

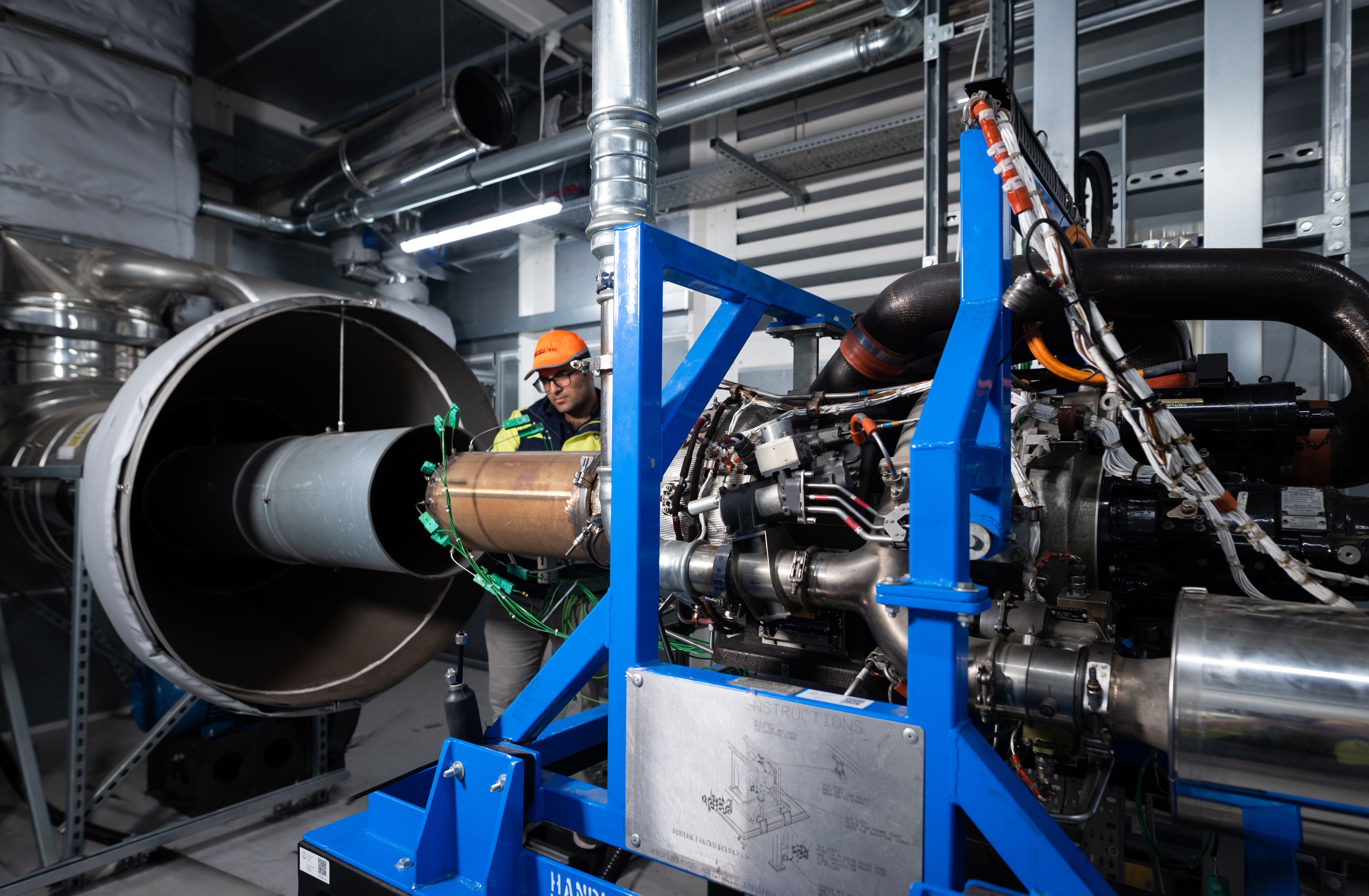

The Energy Innovation Centre (EIC) gives industries access to some of the University’s world class research facilities to test and develop new low-carbon energy technologies. It is one of the largest and best-equipped R&D facilities in the world for low- and zero-carbon technology, with over 30 permanent rigs and a state-of-the-art aviation fuels testing laboratory. Operated by world-leading researchers, the centre is fast-tracking green energy solutions to decarbonize a wide range of industries, with particular strengths in hydrogen, carbon capture usage and storage, and sustainable aviation fuels.

Sheffield’s sustainable aviation fuels laboratory (SAF-IC) is the UK’s first centre to develop, test, validate and certify zero-carbon and sustainable aviation fuels in one location. Given that aviation emissions are a global challenge, the centre accelerates the commercialization and certification of new sustainable fuels, positioning the UK as a global leader in decarbonizing the aviation industry. The UK SAF Clearing House - a platform that provides cross-industry support for the development, testing, qualification and production of sustainable aviation fuels – is also based at the University.

Turning Gene Therapy Research Into Patient Benefit

The Gene Therapy Innovation and Manufacturing Centre (GTIMC) at the University is developing cutting-edge gene therapies and clinical trials, offering hope for patients with conditions such as motor neuron disease, cystic fibrosis, and haemophilia. The centre, which was funded by the Medical Research Council and LifeArc, with support from the Biotechnology and Biological Sciences Research Council, was formed as part of the Innovation Hubs for Gene Therapies. This is a new UK initiative designed to advance the clinical development of new genetic treatments by producing clinical-grade vectors, alongside translational support, and regulatory advice.

The EIC and GTIMIC are both following a similar model to the AMRC by working with businesses to solve industrial challenges. The EIC has two founding members, Boeing and Drax, and collaborates with a wide range of other companies, including Airbus, MissionZero, and Rolls-Royce. These partnerships focus on areas such as sustainable aviation fuel, carbon capture, and clean energy technologies.

Similarly, the GTIMC brings together a network of academic institutions, NHS trusts, non-profit organisations, and industry partners to translate scientific discoveries into new treatments faster. For example, the University has partnered with Sheffield Teaching Hospitals NHS Trust, Sheffield Children's NHS Foundation Trust and the National Institute for Health Research Sheffield Biomedical Research Centre - providing access to a world-class team in driving experimental science into international clinical trials in order to combat devastating diseases and transform millions of lives.

Turning Gene Therapy Research Into Patient Benefit

The Gene Therapy Innovation and Manufacturing Centre (GTIMC) at the University is developing cutting-edge gene therapies and clinical trials, offering hope for patients with conditions such as motor neuron disease, cystic fibrosis, and haemophilia. The centre, which was funded by the Medical Research Council and LifeArc, with support from the Biotechnology and Biological Sciences Research Council, was formed as part of the Innovation Hubs for Gene Therapies. This is a new UK initiative designed to advance the clinical development of new genetic treatments by producing clinical-grade vectors, alongside translational support, and regulatory advice.

The EIC and GTIMIC are both following a similar model to the AMRC by working with businesses to solve industrial challenges. The EIC has two founding members, Boeing and Drax, and collaborates with a wide range of other companies, including Airbus, MissionZero, and Rolls-Royce. These partnerships focus on areas such as sustainable aviation fuel, carbon capture, and clean energy technologies.

Similarly, the GTIMC brings together a network of academic institutions, NHS trusts, non-profit organisations, and industry partners to translate scientific discoveries into new treatments faster. For example, the University has partnered with Sheffield Teaching Hospitals NHS Trust, Sheffield Children's NHS Foundation Trust and the National Institute for Health Research Sheffield Biomedical Research Centre - providing access to a world-class team in driving experimental science into international clinical trials in order to combat devastating diseases and transform millions of lives.

A Successful Model for Research Centres Worldwide

Our translational research centres are bridging the gap between industry needs and curiosity-driven academic research. Since the University of Sheffield AMRC was founded in 2001, it has been committed to creating centres of excellence which make a difference to the advanced manufacturing sector - not only regionally, but nationally and internationally too.

It has successfully become a model for research centres worldwide, demonstrating how working side-by-side with industry partners is the most effective way to tackle complex problems and translate knowledge into economic and societal benefit.

This content was paid for and created by The University of Sheffield. The editorial staff of The Chronicle had no role in its preparation. Find out more about paid content.