Plasma matters: University pioneers unlock secrets to clean eating and reducing food waste

From the lights we turn on to the sun as the source of all life on this planet, plasma, an often unsung but essential state of matter, is involved in every aspect of our daily lives.

Its myriad uses are being investigated by University of Adelaide researchers to improve the foods that we eat, create sustainable food products and reduce food waste.

The University of Adelaide plays a continuing and significant role in research about food production for South Australia and beyond. Research has been central to the economic development of our State, and our ability to improve production amidst challenges including climate change, and the need to develop new crops, and new technologies, to ensure we can continue to flourish in changing conditions.

Dr Bryan Coad, Associate Professor in the School of Agriculture, Food and Wine, is exploring how plasma, perhaps the lesser known of the four states of matter, can be used to extend the shelf life of certain foods, to decontaminate grains, and even to assist with cooking processes.

Plasma may not be as familiar as the three other states of matter – solids, liquids and gasses – because it does not freely exist under normal conditions on Earth. It is, however, quite commonly generated by either lightning, electric sparks, fluorescent and neon lights … and in plasma televisions.

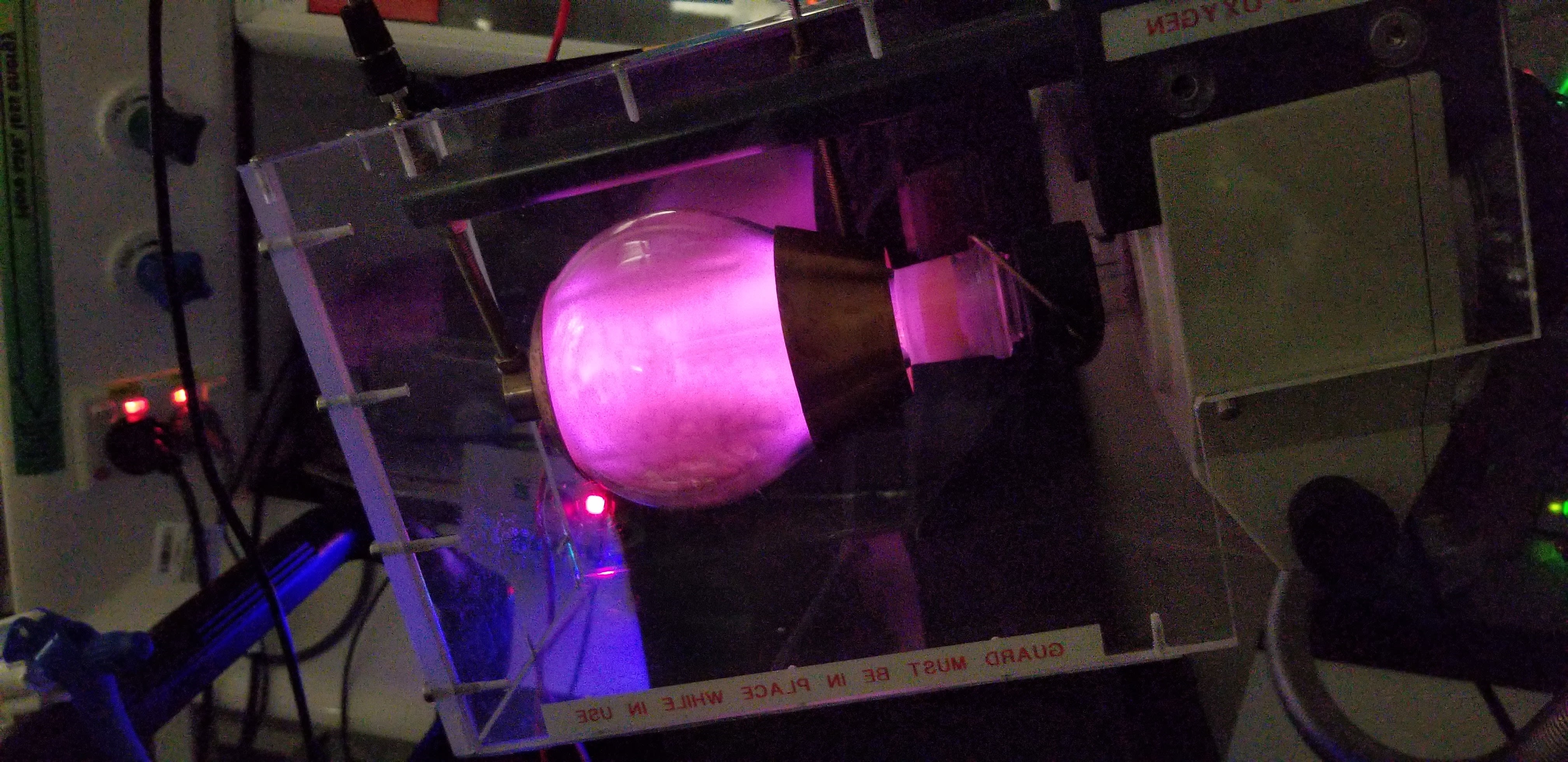

a 500 mL glass vessel contains a glowing pink air plasma discharge and some seeds. A unique feature that ensures the seeds are evenly treated in the plasma discharge is a motor that ensures the seeds tumble in the plasma like clothes in a tumble dryer.

a 500 mL glass vessel contains a glowing pink air plasma discharge and some seeds. A unique feature that ensures the seeds are evenly treated in the plasma discharge is a motor that ensures the seeds tumble in the plasma like clothes in a tumble dryer.

To understand what plasma is, think about what happens when you use energy to boil water and it transforms into steam. Similarly, a gas can be brought into the plasma phase with energy input; however, as opposed to the high energy input that is required to convert water to steam, it is possible to sustain a plasma discharge at low energy if the plasma is generated in a vessel under partial vacuum. The glow in fluorescent light tubes – plasma hard at work – is generated using this principle.

Dr Coad’s research investigates how plasma can benefit life, particularly as communities adapt to and evolve with changing environmental conditions, consumer demand, and the effects of contaminants in global supply chains.

One project explores using plasma to remove fungal contamination from grains to reduce food wastage and lessen risks to human and animal health. Current methods for removing fungal contaminants from grain are often ineffective or may leave behind residues with downstream implications for consumers.

The project explores the use of a novel air plasma tumbler apparatus to spin grain through a field of plasma and inactivate fungal pathogens on the grain surface.

Microbiological techniques were developed to inoculate grain with mycotoxigenic fungal pathogens and surface-sensitive analytical instrumentation was used to understand the physico-chemical changes to grains before and after exposure to plasma. Additionally, researchers monitored short-term seedling growth to understand the effects of plasma treatment on viability and development.

This research applied aspects of microbiology, plasma physics and seed biology to gain insights into the deactivation of grain post-harvest fungal pathogens using air plasma. The outcomes of this systematic study advance the current knowledge of plasma agriculture and promote air plasma as a future technology, benefiting food security and food production, with possible future applications toward biosecurity.

While some see scaling up plasma technologies to industrial scale as a challenge, there are many examples of how R&D has taken bench-top plasma research and delivered profitable, hugely impactful industrial processes and products which includes the Commonwealth Scientific and Industrial Research Organisation’s (CSIRO) fourth most profitable invention, the extended wear contact lens where the plasma coating process is a key component of this invention.

Research at the University of Adelaide has also explored how plasma can be used to soften chickpeas and lentils that require soaking before cooking.

These legumes offer more nutritional value to the human diet than products made from oats and wheat, but in their dried form require processing before they are soft enough for consumption. This study investigated the use of cold plasma pre-treatments on chickpea and lentil grains to improve their textural properties after cooking.

The research found that the textural properties of chickpeas and lentils could be significantly softened by pre-treating these grains with a straightforward processing step using no chemical inputs apart from air and no more energy than what powers your computer monitor. For a given cooking time, plasma-treated grains were much softer, less chewy, and less cohesive, compared to their untreated controls.

The acquired knowledge for how plasma could be used as a pre-treatment process for cooking chickpeas and lentils can be applied to future studies to reduce the time and energy required in industrial processing or home cooking of these nutritionally important legumes.

Plasma discharges can also be bubbled through water to produce a chemical-free. antimicrobial washing solution.

A little over a year ago, a team led by Dr Katharina Richter at the University achieved a major milestone by successfully creating plasma-activated water.

Using Cold Plasma Technology, the team developed an innovative antibacterial solution with transformative potential for food safety. The plasma-activated water effectively neutralises harmful microorganisms, leaving only water, offering a powerful and environmentally friendly disinfectant. This advancement promises to significantly reduce food contamination.

Research funded through the End Food Waste Cooperative Research Centre, with Dr Coad as project manager, is also investigating a novel antimicrobial egg wash in partnership with industry as an alternative to currently used chlorine-based sanitisers.

The plasma water, made by only using an electric discharge, air and water, offers an alternative to chemical processes and aims to increase the shelf life of poultry products. This could contribute to halving Australia’s food waste by 2023.

From making our foods safer, providing nutritious foods, extending the shelf life of products, and reducing food waste, plasma is demonstrating its capacity for a wide range of potential benefits for communities, for sustainability, and for life itself.

This content was paid for and created by University of Adelaide. The editorial staff of The Chronicle had no role in its preparation. Find out more about paid content.